A Study Effect of Hot Air Recirculating Ratio on Drying Behavior of Tilapia by Using a Hot Air Dryer Installed with Stainless Wire Mesh Porous Material

Main Article Content

Abstract

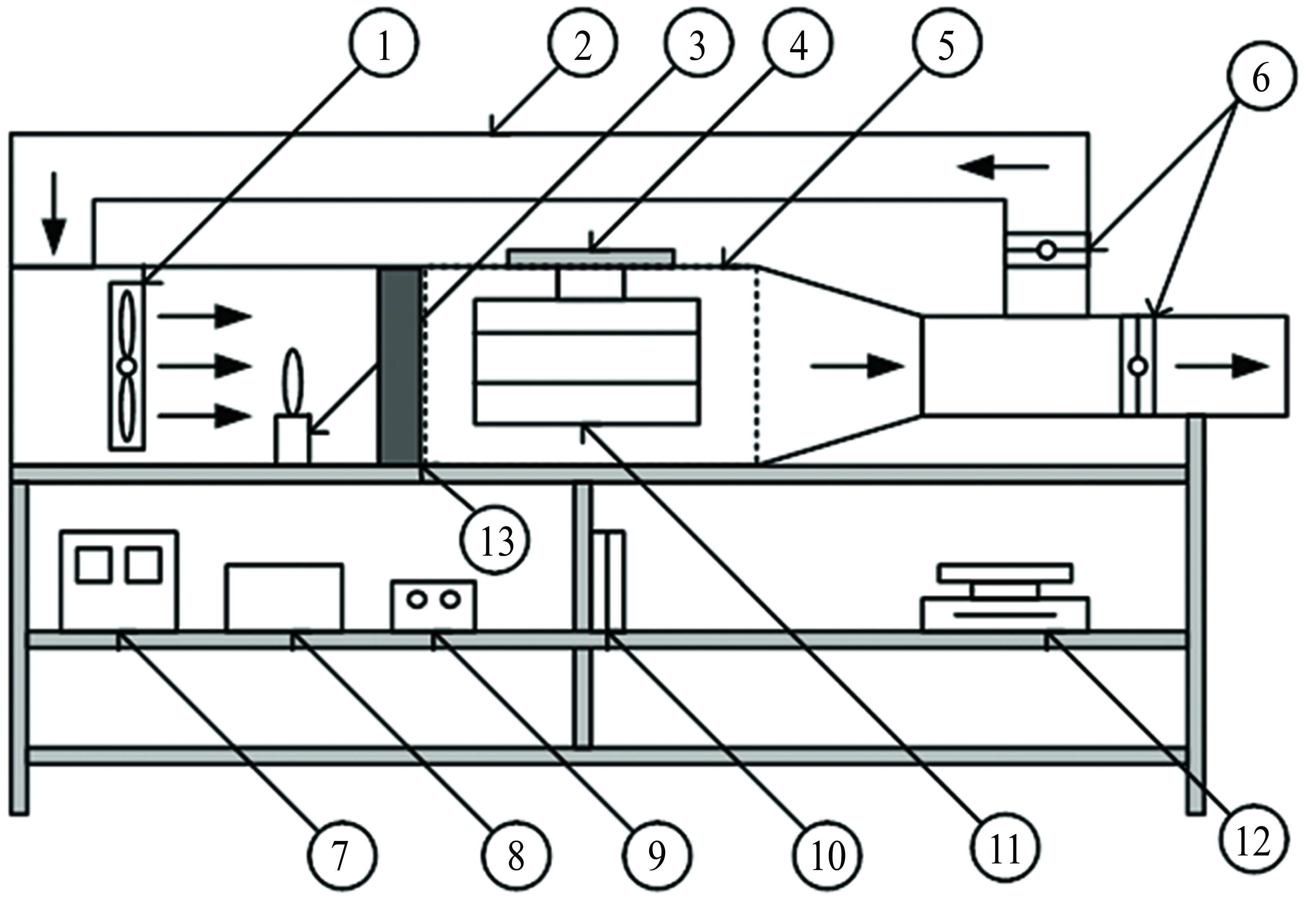

This research aimed to study the effect of hot air recirculating ratio on behavior of tilapia drying by using a hot air dryer by installed with stainless wire mesh porous material. A present dryer was modified by co-operation of recirculating hot air and porous material at the inlet of drying chamber. In experiment, hot air temperature and velocity were maintained at 70 ºC and 2 m/s respectively. Hot air recirculating ratio (Cair) was varied by 0, 40, 60, and 80 %. Tilapia sliced was used as a drying product and mass of tilapia was recorded at interval 20 min during drying process until saturated mass condition. In this study, parameters considered of investigate the drying behavior were: dry basis moisture content (Md), moisture ratio (MR), drying rate (DR) and specific energy consumption (SEC). Thin layer drying models were also discussed in order to predict the drying behavior. From experimental result it was found that DR and Md were decreased as increasing drying time. DR was increased with Cair and Md. Drying time was varied between 420 - 440 min and the highest DR become 0.22 kgwater/min. SEC was decreased as Cair increased. The maximum reduction of SEC being 49.60 % was obtained at Cair = 80 %. The minimum SEC gave 3.14 MJ/kgwater evaporated at Cair = 80 %. For a study on thin layer drying models, the Modified Midilli model was most agreement with experimental result which R2 was more than 0.9964.

Article Details

References

[2] Toomthong, P., Teeboonma, U., Somsila, P., and Homchampa, T. (2012). Study on Drying Behavior of Tilapia nilotica Using Hot Air. Agricultural Science Journal. Vol. 43, 3 (Suppl.) pp. 115-118 (in Thai)

[3] Kesai, S., Kumwan, R., and Chotivisarut, N. (2012). A Potato Chips Dryer Using Infrared Gas Stove. A Thesis for The Degree of Master. Mechanical Engineering. Rajamangala University of Technology Lanna (in Thai)

[4] Duangjun, W., Tunme, S., Cheangsanoi, J., Krittacom, B., and Pongkun, J. (2012). A Study on Tilapia Drying with Hot Air Combine Porous Media. In 7th Engineering Science Technology and Architecture Conference 2012. Dusit Princess Korat, Nakhon Ratchasima, Thailand. pp. 475-479 (in Thai)

[5] Luampon, R. and Krittacom, B. (2016). Study Drying Kinetic of Tilapia using Hot Air Flowing through the Porous Media. In 13th Eco-Energy and Materials Science and Engineering Symposium. Udonthani, Thailand. pp. 325-327.

[6] Jugjai, S. and Polmart, N. (2003). Enhancement of Evaporation and Combustion of Liquid Fuels Through Porous Media. Experimental Thermal and Fluid Science. Vol. 27, pp. 901-909. DOI: 10.1016/S0894-1777(03)00062-1

[7] Luampon, R. (2018). Thin Layer Drying Model of Carrot Using a Heat Pump Vacuum Dryer. The Journal of King Mongkut’s University of Technology North Bangkok. Vol. 28, No. 1, pp. 147-155 (in Thai)

[8] Tippayawong, N., Tantakitti, C., Thavornun, S., and Peerawanitkul, V. (2009). Energy Conservation in Drying of Peeled Longan by Forced Convection and Hot Air Recirculation. Biosystems Engineering. Vol. 104, Issue 2, pp. 199-204. DOI: DOI: 10.1016/j.biosystemseng.2009.06.018

[9] Paengkanya, S., Soponronnarit, S. and Nathakaranakule, A. (2015). Application of Microwaves for Drying of Durian Chips. Food and Bioproducts Processing. Vol. 96, pp. 1-11. DOI: 10.1016/j.fbp.2015.06.001

[10] Baker, C. G. J. (2005). Energy Efficient Dryer Operation-an Update on Developments. Drying Technology. Vol. 23, Issue 9-11, pp. 2071-2087. DOI: 10.1080/07373930500210556

[11] Bruce, D. M. (1985). Exposed-Layer Barley Drying, Three Models Fitted to New Data Up to 150 C. Journal of Agricultural Engineering Research. Vol. 32, pp. 337-347

[12] Page, G. E. (1949). Factors Influencing the Maximum Rate of Air Drying Shelled Corn in Thin Layers. M.S. thesis. Department of Mechanical Engineering. Purdue University, Purdue, USA

[13] White, G. M., Ross, I. J., and Ponelert, R. (1981). Fully Exposed Drying of Popcorn. Transactions of the ASAE. Vol. 24, pp. 466-468

[14] Henderson, S. M. and Pabis, S. (1961). Grain Drying Theory II Temperature Effects on Drying Coefficients. Journal of Agricultural Engineering Research. Vol. 6, pp. 169-174

[15] Togrul, I. T. and Pehlivan, D. (2002). Mathematical Modeling of Solar Drying of Apricots in thin Layers. Journal of Food Engineering. Vol. 55, pp. 209-216. DOI: 10.1016/S0260-8774(02)00065-1

[16] Henderson, S. M. (1974). Progress in Developing the Thin Layer Drying Equation. Transactions of ASAC. Vol. 17, pp. 1167-1172

[17] Yaldiz, O., Ertekin, C., and Uzun, H. I. (2001). Mathematical Modeling of Thin Layer Solar Drying of Sultana Grapes. Energy. Vol. 26, Issue 5, pp. 457-465. DOI: 10.1016/S0360-5442(01)00018-4

[18] Wang, C. Y. and Singh, R. P. (1978). Use of Variable Equilibrium Moisture Content in Modeling Rice Drying. Transactions of American Society of Agricultural Engineers. Vol. 11, pp. 668-672

[19] Diamante, L. M. and Munro, P. A. (1991). Mathematical Modeling of Hot Air Drying of Sweet Potato Slices. International Journal of Food Science and Technology. Vol. 26, Issue 1, pp. 99-108. DOI: 10.1111/j.1365-2621.1991.tb01145.x

[20] Midilli, A., Kucuk, H., and Yapar, Z. (2002). A New Model for Single Layer Drying. Drying Technology. Vol. 20, Issue 7, pp. 1503-1513. DOI: 10.1081/DRT-120005864

[21] Charmongkolpradit, S. and Luampon, R. (2017). Study of Thin Layer Drying Model for Cassava Pulp. Energy Procedia. Vol. 138, pp. 354-359. DOI: 10.1016/j.egypro.2017.10.138

[22] Akgun, N. A. and Doymaz, I. (2005). Modeling of Olive Cake Thin-Layer Drying Process. Journal of Food Engineering. Vol. 68, Issue 4, pp. 455-461. DOI: 10.1016/j.jfoodeng.2004.06.023