Design and Development of the Crispy Flossy Pork Fryer Prototype Machine of Ban Nong Luang Valunteer for Rural Development Women Group’s OTOP for Exporting to AEC

Main Article Content

Abstract

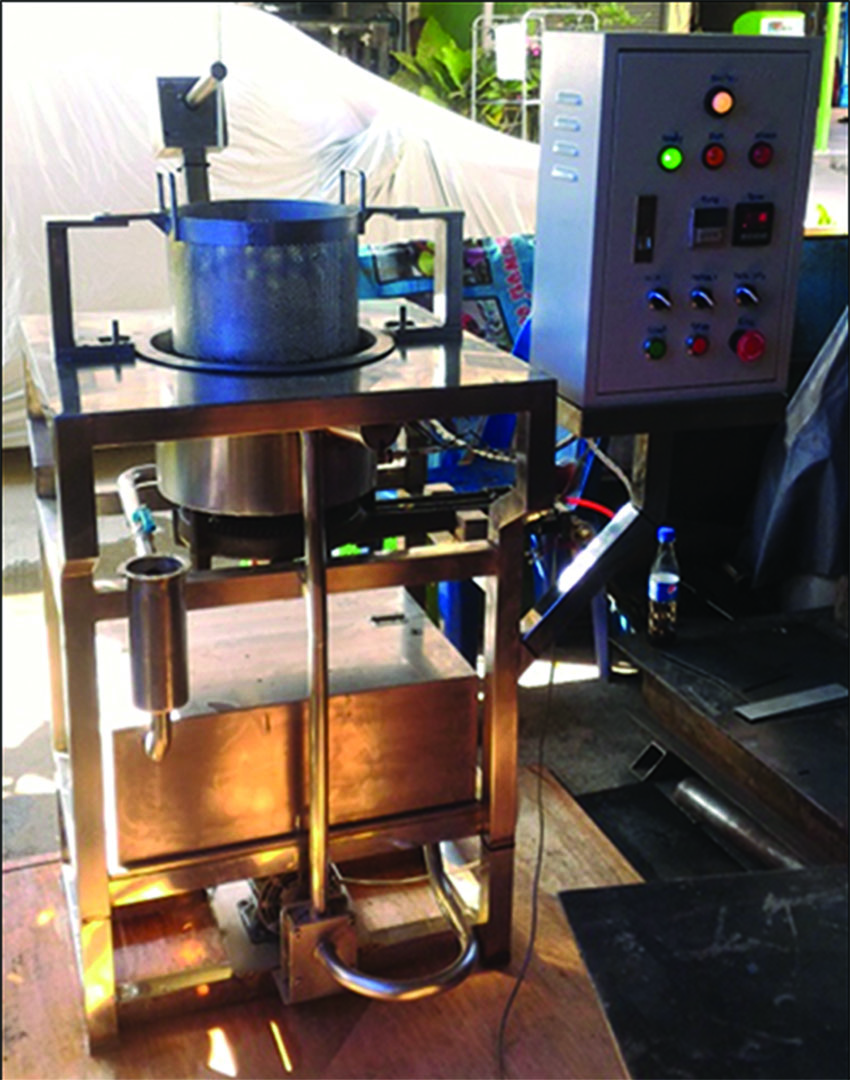

Crispy Flossy Pork frying machine is designed and built for the purpose of developing and studying process in frying Crispy Flossy Pork in order to ensure a good quality, convenience, and reduce workforce and cost in producing fried Crispy Flossy Pork. The machine will be used in small to medium enterprise and transform Crispy Flossy Pork in order to sell them. Prototype of the machine comprises a machine frame, an oil pot with 300 mm in dimeter and 200 mm in depth, a deep fly sieve with 240 mm in dimeter and 170 mm in depth. The stirring blade has 220 mm radius. It used 25 W motor as a driving force and heater from the gas LPG. The machine works by pouring oil into the pot and open the fire. When the oil is hot at the setting temperature the Crispy Flossy Pork are poured into the oil. The experiment shows that the prototype machine can work best when temperature of the oil is at 121 - 130 oC with frying oil filtration. The machine can fry up to 3 kg of Crispy Flossy Pork within 16 minute the reused oil could be done up to 13 times while maintaining polar substances at 25 % or less Therefore yielding fried shallots with good quality and safe to consumers is obtained. And reduce fatigue from old frying.

Article Details

References

[2] Fennema, O. R. (1985). Food Chemistry. 2nd ed., New York, U.S.A.: Marcel Dekker Inc.,

[3] Fircotone, D., Stier, R. F., and Blurnenthal, M. M. (1991). Regulation of Frying Fats and Oil. Food Technology. Vol. 45, No. 2, pp. 90-94

[4] Suparat, C., Inpunyo, C., and Torsakul, S. (2017). Design and Development of Shallot Frying Machine. Journal of Engineering, RMUTT. Vol. 15, No. 2, pp. 51-57 (in Thai)

[5] Krutz, G., Thomson, L., and Claar, P. (1994). Design of Agricultural Machinery. John Wiley and Sons. New York Chicheter Brisbne, Toronto, Sigapore. p. 472

[6] Shigley, J. E. and Mischke, C. R. (1989). Mechanical Engineering Design. Edition, McGraw-Hill Book Company, USA. p. 779

[7] Ruecha, A. and Srila, M. (2015). Banana Slider Machine. Prawarun Agricultural Journal. Vol. 12, No. 2, pp. 136-143 (in Thai)

[8] Research Projects Reassurance of Refined Oil Quality Several Times to Reduce the Risk of Consumers’ Health. (2002). Lipid and Fat Center Faculty of Allied Health Sciences, Chulalongkorn University. Access (30 February 2016). Available (https://food.fda.moph.go.th/data/document/2554/CS04.pdf)

[9] Department of Medical Sciences Ministry of Public Health. (n.d.). Guide to Food Test Kit. Access (24 February 2016). Available (https://dmsc2.dmsc.moph.go.th/webroot/BQSF/File/food_safety/document/foodsafety%20manual_fulltext.pdf)

[10] SANSABAY SHOP. (2012). Polar Tester in Frying Oil. Access (24 February 2016). Available (https://www.sansabaytwelve.com/f015.php)