A Study of the Thermal Efficiency of A Double-Air Inlet Doors Charcoal Stove

Main Article Content

Abstract

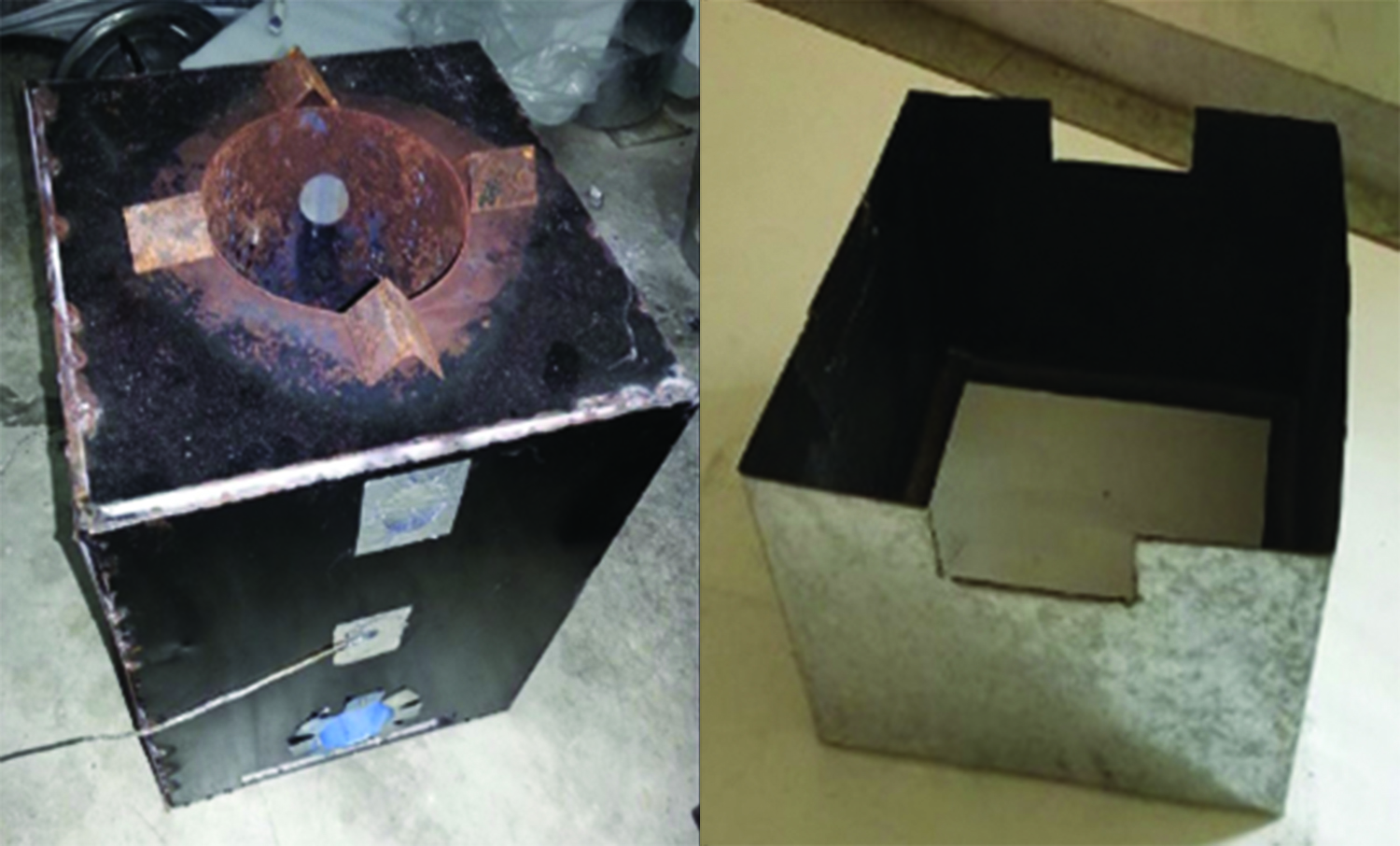

The objectives of this research were to study the effects on thermal efficiency of the amount of air entering through a double-air inlet doors charcoal stove. The experiment method was carried out following the WBT. The trials were divided into three phases: Trials on the high power (cold start), trials on the high power (hot start) and trials at low power (simmering). Four Trials were conducted. The first trial opened only one of the two inlets fully (100 %, 0 %). The second trial fully opened both inlets (100 %, 100 %). The third trial opened both inlets by half (50 %, 50 %). The last trial used a pot cover in addition to the third trial. The test results indicated that the thermal efficiency of the third trial increased to 42.75 %, higher than the first trial (19.50 %). The condition to slow down the exhaust gas by the pot cover in the last trial gave the highest efficiency value of 50.75 % and the combustion temperature was higher, also the specific fuel consumption was decreased.

Article Details

References

[2] Thai Industrial Standard Institute. TCPS.658/2547 Thai Community Product Standard Wood Charcoal for Grilling. Ministry of Industry

[3] Thai Industrial Standard Institute. TCPS.443/2547 Thai Community Product Standard Charcoal Stove. Ministry of Industry

[4] Kaewluan, S., Chantosee, D., Chansri, S., and Piyarat, W. (2013). Performance Testing of the 20 kW Biomass Gas Stove. SWU Engineering Journal. Vol. 8, No. 1, pp. 24-33 (in Thai)

[5] Janjit, J. and Matthujak, A. (2009). Thermal Efficiency Improvement of Household Cooking Burner by Porous Radiant Recirculated Cover. The 23rd Conferrence of The Mechanical

Engineering Network of Thailand. AEC-006248. Chiang Mai. Secretariat of ME-NETT 23 - THAILAND. (in Thai)

[6] Chaichana, T., Ali, M., and Longsaman, M. (2013). The Study of Thermal Efficiency of Household Cooking Stove. Journal of Science and Technology Mahasarakham University.

Vol. 32, No. 5, pp. 626-630 (in Thai)

[7] Chorchong, T. and Im-in, W. (2014). Program Simulation of Efficiency Stove and Dowd-draft Gasifier Biomass Stove. In Proceedings of the Pibulsongkram Research Conferrence.

Pibulsongkram Rajabhat University. pp. 75-82 (in Thai)

[8] Sae-ung, P. and Vichanong, N. (2010). Feasibility Study of Agricultural Waste Application for Briquette Fuel. The 7th KU-KPS Conference. Kasetsart University Kamphaeng Saen

Campus. pp.711-717 (in Thai)

[9] Sanasen, P. (1968). A Comparative Study in The Use of Charcoal and Gas for Cooking. Master’s Thesis. Faculty of Agriculture, Kasetsart University. (in Thai)

[10] Kumar, A., Prasad, M., and Mishra, K. P. (2013). Coparative Study of Effect of Different Parameters on Performance and Emission of Biomass Cook Stove. International Journal of

Research in Engineering & Technology. Vol. 1, Issue 3, pp. 121-126

[11] Kryvongwon, P. (2003). Testing and Efficiency Improvement of Charcoal Stove. Master’s Thesis. Energy Management Technology. School of Energy and Materials. King Mongkut’s

University of Technology Thonburi. (in Thai)

[12] Kshirsagar, M. P. (2009). Experimental Study for Improving Energy Efficiency of Charcoal Stove. Journal of Scientific & Industrial Research. Vol. 68, pp. 412-416

[13] Panklib, T. (2014). Equipment for Increases Efficiency of Cooking Stove and Power Generator. The Journal of Applied Science. Vol. 13, No. 1, pp.1-13

[14] Promdon, A. and Sriveeraku, T. (2012). Thermal Efficiency Test of High Efficiency Cooking Stove (HECS) with Variations on the Number and Diameter Ratio of the Grate’s Holes. The 26rd Conference of the Mechanical Engineering Network of Thailand. ATM-2010. Chiang Rai. Secretariat of ME-NETT 26 - THAILAND.

[15] Wichangarm, M. and Sriveeraku, T. (2012). Simulation of Air Flow through a High Efficiency Cooking Stove’s Grate using CFD. Journal of Science and Technology Ubon Ratchathani University. Vol. 14, No. 2, pp 24-34 (in Thai)

[16] Obaidullah, M., Dyakov, I. V., Thomassin, J. D., Duquesne, T., Bramc, S., Contino, F., and De Ruyck, J. (2014). CO Emission Measurements and Performance Analysis of 10 kW and 20 kW Wood Stoves. Energy Procedia. Vol. 61, pp. 2301-2306. DOI: 10.1016/j.egypro.2014.12.443

[17] Global Alliance for Clean Cookstove. (2015). The Water Boiling Test. Cookstove Emissions and Efficiency in a Controlled Laboratory Setting. Ver. 4.2.3. Access (17 March 2015). Available (http://cleancookstoves.org/binary-data/DOCUMENT/fi le/000/000/399-1.pdf)